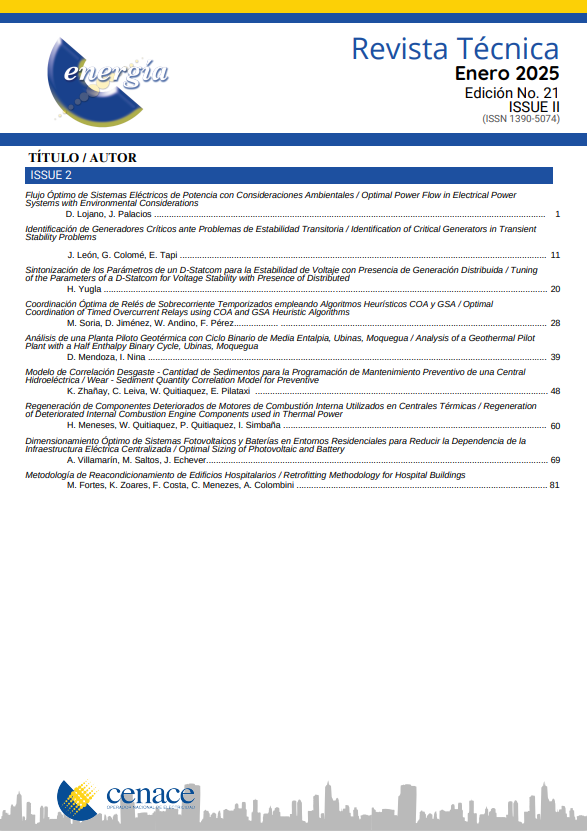

Regeneration of Deteriorated Internal Combustion Engine Components used in Thermal Power Plants

Regeneración de Componentes Deteriorados de Motores de Combustión Interna Utilizados en Centrales Térmicas

How to Cite

Download Citation

Show authors biography

Similar Articles

- Johnny Heredia, Edy Ayala , IoT and AI-Based Predictive Maintenance System Design for Express Auto Repair Shops , Revista Técnica "energía": Vol. 21 No. 2 (2025): Revista Técnica "energía", Edición No. 21, ISSUE II

- Fernando Toapanta, Melany Oña, Numerical Study with CFD of the Refrigeration in a Vehicle Cabin with two Refrigerants R32 and R600a , Revista Técnica "energía": Vol. 21 No. 1 (2024): Revista Técnica "energía", Edición No. 21, ISSUE I

- Marco Rosero, Morayma Muñoz, Jessenia Ayala, Angela García, Antonio Marcilla, Carla Zambonino, Najhely García, Evaluation of the Energy Storage Capacity of Cocoa Lignocellulosic Material , Revista Técnica "energía": Vol. 21 No. 1 (2024): Revista Técnica "energía", Edición No. 21, ISSUE I

- Alex Rivera, William Quitiaquez, Isaac Simbaña, Patricio Quitiaquez, Study of Steam Generation and Distribution in a Hospital to Improve Energy Efficiency Using Thermography, Ultrasound, and Gas Analyzer , Revista Técnica "energía": Vol. 20 No. 2 (2024): Revista Técnica "energía", Edición No. 20, ISSUE II

- Kleber Zhañay, Cristian Leiva, Erika Pilataxi, William Quitiaquez, Wear - Sediment Quantity Correlation Model for Preventive Maintenance Scheduling of a Hydroelectric Power Plant , Revista Técnica "energía": Vol. 21 No. 2 (2025): Revista Técnica "energía", Edición No. 21, ISSUE II

- Morayma Muñoz, Napoleón Padilla, Grace Morrillo, Marco Rosero, Electrocoagulation as a Sustainable Alternative for the Treatment of Refinery Effluents: Application in Esmeraldas Refinery , Revista Técnica "energía": Vol. 22 No. 1 (2025): Revista Técnica "energía", Edición No. 22, ISSUE I

- William Quitiaquez, Andrés Argüello, Isaac Simbaña, Patricio Quitiaquez, Evaluation of the gasoline engines behavior by the air flow simulation through the throttle body , Revista Técnica "energía": Vol. 20 No. 1 (2023): Revista Técnica "energía", Edición No. 20, ISSUE I

- Isaac Simbaña, Cristian Guilcaso, Fabricio Tipantocta, Energy and Environmental Assessment of a Solar-Assisted Heat Pump for Water Heating , Revista Técnica "energía": Vol. 22 No. 2 (2026): Revista Técnica "energía", Edición No. 22 ISSUE II

- Marcio Zamboti , Keren Tenório , Fabricio Toscano, Carolina Cunha, Angelo Cesar, Retrofitting Methodology for Hospital Buildings , Revista Técnica "energía": Vol. 21 No. 2 (2025): Revista Técnica "energía", Edición No. 21, ISSUE II

- Isaac Simbaña, William Quitiaquez, Patricio Cabezas, Patricio Quitiaquez, Comparative study of the efficiency of rectangular and triangular flat plate solar collectors through finite element method , Revista Técnica "energía": Vol. 20 No. 2 (2024): Revista Técnica "energía", Edición No. 20, ISSUE II

You may also start an advanced similarity search for this article.

Most read articles by the same author(s)

- William Quitiaquez, Isaac Simbaña, Robinson Caizatoa, César Isaza, César Nieto, Patricio Quitiaquez, Fernando Toapanta, Analysis of the thermodynamic performance of a solar-assisted heat pump using a condenser with recirculation , Revista Técnica "energía": Vol. 16 No. 2 (2020): Revista Técnica "energía", Edición No. 16

- Isaac Simbaña, William Quitiaquez, Patricio Cabezas, Patricio Quitiaquez, Comparative study of the efficiency of rectangular and triangular flat plate solar collectors through finite element method , Revista Técnica "energía": Vol. 20 No. 2 (2024): Revista Técnica "energía", Edición No. 20, ISSUE II

- Carlos Maigua, William Quitiaquez, Isaac Simbaña, Patricio Quitiaquez, Fernando Toapanta, César Isaza, Diseño de un Sistema de Monitoreo de Vibraciones Mecánicas en Generadores Hidroeléctricos de Media Potencia , Revista Técnica "energía": Vol. 17 No. 1 (2020): Revista Técnica "energía", Edición No. 17, ISSUE I

- Jonnathan Morales, William Quitiaquez, Isaac Simbaña, Mathematics optimization models for downstream and midstream petroleum sectors. Literature review and future research directions , Revista Técnica "energía": Vol. 17 No. 1 (2020): Revista Técnica "energía", Edición No. 17, ISSUE I

- Fernando Toapanta, Jairo Cortéz, William Quitiaquez, Wilson Orellana, Numerical Study Using CFD of the Cooling Process with Heat Exchangers in Computer Systems , Revista Técnica "energía": Vol. 17 No. 2 (2021): Revista Técnica "energía", Edición No. 17, ISSUE II

- William Quitiaquez, Andrés Argüello, Isaac Simbaña, Patricio Quitiaquez, Evaluation of the gasoline engines behavior by the air flow simulation through the throttle body , Revista Técnica "energía": Vol. 20 No. 1 (2023): Revista Técnica "energía", Edición No. 20, ISSUE I

- Alex Rivera, William Quitiaquez, Isaac Simbaña, Patricio Quitiaquez, Study of Steam Generation and Distribution in a Hospital to Improve Energy Efficiency Using Thermography, Ultrasound, and Gas Analyzer , Revista Técnica "energía": Vol. 20 No. 2 (2024): Revista Técnica "energía", Edición No. 20, ISSUE II

- Isaac Simbaña, William Quitiaquez, José Estupiñán, Fernando Toapanta-Ramos, Leonidas Ramírez, Performance evaluation of a direct expansion solar-assisted heat pump by numerical simulation of the throttling process in the expansion device , Revista Técnica "energía": Vol. 19 No. 1 (2022): Revista Técnica "energía", Edición No. 19, ISSUE I

- William Quitiaquez, Christian Cholca, Erika Pilataxi, Fernando Toapanta, Evaluation of Flexible Configuration Pipeline Networks for Hydrocarbon Transportation , Revista Técnica "energía": Vol. 20 No. 1 (2023): Revista Técnica "energía", Edición No. 20, ISSUE I

- William Quitiaquez, Jorge Chimarro, John Valarezo, Patricio Quitiaquez, César Melendrez, Fernando Toapanta, Validation of a prototype of three-phase energy meter as support for an energy audit , Revista Técnica "energía": Vol. 17 No. 2 (2021): Revista Técnica "energía", Edición No. 17, ISSUE II

The generation of electric power through internal combustion engines plays an important role in the world economy. Exhaust cases and valves are critical engine components and are subjected to high pressures and temperatures. The additive remanufacturing technology of mechanical components that have reached the end of their useful life due to wear, through the L-DED laser directed energy deposition method, proves to be an effective method to obtain spare parts with similar or even superior characteristics to a new part, extending the product life cycle in the circular economy. The process consists of obtaining 3D models through reverse engineering, additive remanufacturing by L-DED and final machining. It was determined through the study that this methodology can be successfully applied to the exhaust boxes and valves of internal combustion engines for electric generation. The results obtained have shown that this remanufacturing method is an effective solution for the recovery of exhaust boxes and valves that have completed their useful life and can be applied to other engine elements, reducing the cost of the spare part compared to a new one and bringing with it important environmental benefits. In reference to the remanufacturing time, it has been determined that the application of the L-DED process in the exhaust boxes and valves is 3943 and 3677 s respectively. In addition to this time, the time used in the initial preparation and final machining must be added; however, the time is substantially less than the manufacturing of a new spare part, which brings with it an increase in the availability of these spare parts to perform scheduled maintenance in the engines for power generation, contributing to improve the efficiency of the national electric system.

Article visits 912 | PDF visits 197

Downloads

- D. Bocchetti, M. Giorgio, M. Guida, and G. Pulcini, “A competing risk model for the reliability of cylinder liners in marine Diesel engines,” Reliab. Eng. Syst. Saf., vol. 94, no. 8, pp. 1299–1307, 2009, doi: https://doi.org/10.1016/j.ress.2009.01.010.

- S. Vasilevish, A. Warouma, and S. Vasilevish, “Restoration of bronze bushes by the method of surface plastic deformation,” Int. J. Eng. Technol., vol. 5, p. 29, 2016, doi: 10.14419/ijet.v5i1.5651.

- A. Permyakov, Y. Nemyrovskyi, E. Posviatenko, and I. Shepelenko, “Methodology of technological design in the restoration of parts,” IOP Conf. Ser. Mater. Sci. Eng., vol. 1277, no. 1, p. 12013, Mar. 2023, doi: 10.1088/1757-899X/1277/1/012013.

- Rahito, D. A. Wahab, and A. H. Azman, “Additive Manufacturing for Repair and Restoration in Remanufacturing: An Overview from Object Design and Systems Perspectives,” Processes, vol. 7, no. 11, 2019, doi: 10.3390/pr7110802.

- W. Quitiaquez et al., “Análisis del rendimiento termodinámico de una bomba de calor asistida por energía solar utilizando un condensador con recirculación,” Rev. Técnica “Energía,” vol. 16, no. 2, pp. 111–125, 2020, doi: 10.37116/revistaenergia.v16.n2.2020.358.

- Y. Lahrour and D. Brissaud, “A Technical Assessment of Product/Component Re-manufacturability for Additive Remanufacturing,” Procedia CIRP, vol. 69, pp. 142–147, 2018, doi: https://doi.org/10.1016/j.procir.2017.11.105.

- S. Yin et al., “Cold spray additive manufacturing and repair: Fundamentals and applications,” Addit. Manuf., vol. 21, pp. 628–650, 2018, doi: https://doi.org/10.1016/j.addma.2018.04.017.

- H. Assadi, H. Kreye, F. Gärtner, and T. Klassen, “Cold spraying – A materials perspective,” Acta Mater., vol. 116, pp. 382–407, 2016, doi: https://doi.org/10.1016/j.actamat.2016.06.034.

- J. C. Najmon, S. Raeisi, and A. Tovar, “2 - Review of additive manufacturing technologies and applications in the aerospace industry,” in Additive Manufacturing for the Aerospace Industry, F. Froes and R. Boyer, Eds., Elsevier, 2019, pp. 7–31. doi: https://doi.org/10.1016/B978-0-12-814062-8.00002-9.

- S. Peng et al., “An integrated decision model of restoring technologies selection for engine remanufacturing practice,” J. Clean. Prod., vol. 206, pp. 598–610, 2019, doi: https://doi.org/10.1016/j.jclepro.2018.09.176.

- R. Huang, M. Sone, W. Ma, and H. Fukanuma, “The effects of heat treatment on the mechanical properties of cold-sprayed coatings,” Surf. Coatings Technol., vol. 261, pp. 278–288, 2015, doi: https://doi.org/10.1016/j.surfcoat.2014.11.017.

- Q. Xiang, H. Zhang, Z. Jiang, S. Zhu, and W. Yan, “A decision-making method for active remanufacturing time based on environmental and economic indicators,” Int. J. Online Eng., vol. 12, no. 12, pp. 32–37, 2016, doi: 10.3991/ijoe.v12i12.6455.

- G. Barragan, D. A. Rojas Perilla, J. Grass Nuñez, F. Mariani, and R. Coelho, “Characterization and Optimization of Process Parameters for Directed Energy Deposition Powder-Fed Laser System,” J. Mater. Eng. Perform., vol. 30, no. 7, pp. 5297–5306, 2021, doi: 10.1007/s11665-021-05762-9.

- Y. Zhao, J. Sun, Z. Jia, W. Cheng, and J. Wang, “Research on Laser Additive and Milling Subtractive Composite Remanufacturing Process of Compressor Blade,” J. Manuf. Mater. Process., vol. 2, no. 4, 2018, doi: 10.3390/jmmp2040073.

- X. Zhang, W. Li, K. M. Adkison, and F. Liou, “Damage reconstruction from tri-dexel data for laser-aided repairing of metallic components,” Int. J. Adv. Manuf. Technol., vol. 96, no. 9, pp. 3377–3390, 2018, doi: 10.1007/s00170-018-1830-3.

- A. Shrivastava, A. K. S., S. Rao, N. B.K., S. Barad, and S. T.N., “Remanufacturing of nickel-based aero-engine components using metal additive manufacturing technology,” Mater. Today Proc., vol. 45, pp. 4893–4897, 2021, doi: https://doi.org/10.1016/j.matpr.2021.01.355.

- A. Carmona, F. Delfin, A. Maskavizan, and S. Brühl, “Análisis comparativo de recubrimientos duros de DLC y TiSiCN frente al desgaste y a la corrosión,” Matéria (Rio Janeiro), vol. 28, 2023, doi: 10.1590/1517-7076-rmat-2022-0312.

- S. Zhu, W. Du, X. Wang, G. Han, Z. Ren, and K. Zhou, “Advanced Additive Remanufacturing Technology,” Chinese J. Mech. Eng. Addit. Manuf. Front., vol. 2, no. 1, p. 100066, 2023, doi: https://doi.org/10.1016/j.cjmeam.2023.100066.

- R. Kian, T. Bektaş, and D. Ouelhadj, “Optimal spare parts management for vessel maintenance scheduling,” Ann. Oper. Res., vol. 272, no. 1, pp. 323–353, 2019, doi: 10.1007/s10479-018-2907-y.

- J. Zhou, T. Li, and D. Wang, “A Novel Approach of Studying the Fluid–Structure–Thermal Interaction of the Piston–Cylinder Interface of Axial Piston Pumps,” Appl. Sci., vol. 11, no. 19, 2021, doi: 10.3390/app11198843.

- K. P. Dahal and N. Chakpitak, “Generator maintenance scheduling in power systems using metaheuristic-based hybrid approaches,” Electr. Power Syst. Res., vol. 77, no. 7, pp. 771–779, 2007, doi: https://doi.org/10.1016/j.epsr.2006.06.012.

- I. Simbaña, W. Quitiaquez, J. Estupiñán, F. Toapanta-Ramos, and L. Ramírez, “Evaluación del rendimiento de una bomba de calor de expansión directa asistida por energía solar mediante simulación numérica del proceso de estrangulamiento en el dispositivo de expansión,” Rev. Técnica “energía,” vol. 19, no. 1, pp. 110–119, 2022, doi: 10.37116/revistaenergia.v19.n1.2022.524.

- A. Froger, M. Gendreau, J. E. Mendoza, É. Pinson, and L.-M. Rousseau, “Maintenance scheduling in the electricity industry: A literature review,” Eur. J. Oper. Res., vol. 251, no. 3, pp. 695–706, 2016, doi: https://doi.org/10.1016/j.ejor.2015.08.045.

- D. Svetlizky et al., “Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications,” Mater. Today, vol. 49, pp. 271–295, 2021, doi: https://doi.org/10.1016/j.mattod.2021.03.020.

- G. Piscopo and L. Iuliano, “Current research and industrial application of laser powder directed energy deposition,” Int. J. Adv. Manuf. Technol., vol. 119, no. 11, pp. 6893–6917, 2022, doi: 10.1007/s00170-021-08596-w.

- A. J. Pinkerton, “16 - Laser direct metal deposition: theory and applications in manufacturing and maintenance,” in Advances in Laser Materials Processing, J. Lawrence, J. Pou, D. K. Y. Low, and E. Toyserkani, Eds., in Woodhead Publishing Series in Welding and Other Joining Technologies. , Woodhead Publishing, 2010, pp. 461–491. doi: https://doi.org/10.1533/9781845699819.6.461.

- R. Liu, Z. Wang, T. Sparks, F. Liou, and J. Newkirk, “13 - Aerospace applications of laser additive manufacturing,” in Laser Additive Manufacturing, M. Brandt, Ed., in Woodhead Publishing Series in Electronic and Optical Materials. , Woodhead Publishing, 2017, pp. 351–371. doi: https://doi.org/10.1016/B978-0-08-100433-3.00013-0.

- H. Wang et al., “Review on adaptive control of laser-directed energy deposition,” Opt. Eng., vol. 59, no. 07, p. 1, 2020, doi: 10.1117/1.oe.59.7.070901.

- C. Barr, R. A. Rahman Rashid, S. Palanisamy, J. Watts, and M. Brandt, “Examination of steel compatibility with additive manufacturing and repair via laser directed energy deposition,” J. Laser Appl., vol. 35, no. 2, 2023, doi: 10.2351/7.0000952.

- D. K. Kim, D. Y. Kim, S. H. Ryu, and D. J. Kim, “Application of nimonic 80A to the hot forging of an exhaust valve head,” J. Mater. Process. Technol., vol. 113, no. 1, pp. 148–152, 2001, doi: https://doi.org/10.1016/S0924-0136(01)00700-2.

- Z. Lestan, M. Milfelner, J. Balic, M. Brezocnik, and I. Karabegovic, “Laser deposition of Metco 15E, Colmony 88 and VIM CRU 20 powders on cast iron and low carbon steel,” Int. J. Adv. Manuf. Technol., vol. 66, no. 9, pp. 2023–2028, 2013, doi: 10.1007/s00170-012-4478-4.

- V. Shankar, K. Bhanu Sankara Rao, and S. L. Mannan, “Microstructure and mechanical properties of Inconel 625 superalloy,” J. Nucl. Mater., vol. 288, no. 2, pp. 222–232, 2001, doi: https://doi.org/10.1016/S0022-3115(00)00723-6.

- S. Pratheesh Kumar, S. Elangovan, R. Mohanraj, and J. R. Ramakrishna, “A review on properties of Inconel 625 and Inconel 718 fabricated using direct energy deposition,” Mater. Today Proc., vol. 46, pp. 7892–7906, 2021, doi: https://doi.org/10.1016/j.matpr.2021.02.566.

- A. Strondl, R. Fischer, G. Frommeyer, and A. Schneider, “Investigations of MX and γ′/γ″ precipitates in the nickel-based superalloy 718 produced by electron beam melting,” Mater. Sci. Eng. A, vol. 480, pp. 138–147, 2008, doi: 10.1016/j.msea.2007.07.012.

- Y. L. Hu, Y. L. Li, S. Y. Zhang, X. Lin, Z. H. Wang, and W. D. Huang, “Effect of solution temperature on static recrystallization and ductility of Inconel 625 superalloy fabricated by directed energy deposition,” Mater. Sci. Eng. A, vol. 772, p. 138711, 2020, doi: https://doi.org/10.1016/j.msea.2019.138711.

- Z. Li, J. Chen, S. Sui, C. Zhong, X. Lu, and X. Lin, “The microstructure evolution and tensile properties of Inconel 718 fabricated by high-deposition-rate laser directed energy deposition,” Addit. Manuf., vol. 31, p. 100941, 2020, doi: https://doi.org/10.1016/j.addma.2019.100941.

- H. González-Barrio, A. Calleja-Ochoa, L. Norberto López de Lacalle, and A. Lamikiz, “Hybrid manufacturing of complex components: Full methodology including laser metal deposition (LMD) module development, cladding geometry estimation and case study validation,” Mech. Syst. Signal Process., vol. 179, p. 109337, 2022, doi: https://doi.org/10.1016/j.ymssp.2022.109337.